The predecessor to Industry 5.0, Industry 4.0, represented a significant leap in technological advancement in manufacturing through data, or more precisely the interoperability between existing systems, enabling more flexibility and intelligence in factories. Terms such as smart factory and Internet of Things are strongly linked to the concept. However, while Industry 4.0 has had a large impact on operations, it has failed to place the challenges faced and recent development made by the industry in the context of pressing global challenges such as climate change and social inequality. Thus, while many businesses still have their eyes on Industry 4.0, more and more are beginning to look beyond the horizon and towards Industry 5.0 and the global agenda.

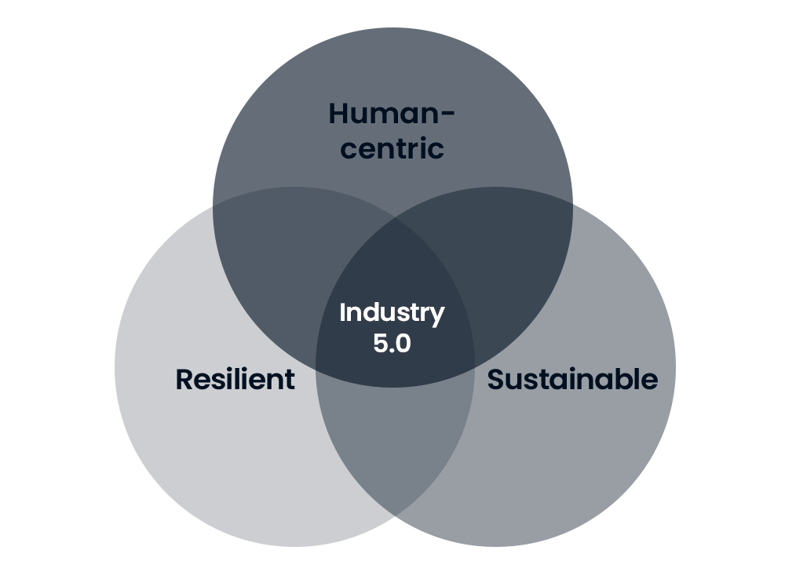

Rooted in the European Union's industrial strategy, the transition to Industry 5.0 marks a pivotal moment, representing a paradigm shift towards a more sustainable, human-centric, and resilient industrial future. While one can argue that within Industry 4.0 and even its predecessor 3.0, technology has increased efficiency and safety, which in turn can for example lead to decreased waste and energy usage, the main difference lies in a shift from mainly economic incentives to a more holistic perspective of industry as a part of greater society.

Industry 5.0 redefines the purpose of industry, placing the well-being of workers and the planet at the forefront of the production process. This transition is driven by a comprehensive vision, encompassing sustainability, circularity, digital transformation, worker empowerment, and societal impact.

Image: The Three Pillars of Industry 5.0 based on the EU Publication "Industry 5.0 Human-centric, sustainable and resilient" as adopted by Forbes.

Let's dive deeper into the core principles and components driving the transformation.

Goals and objectives:

The goals of Industry 5.0 are multi-faceted, encompassing a wide range of objectives aimed at fostering resilience, sustainability, and human-centricity within the industrial sector. These objectives include:

Sustainability:

Promoting circular production models, resource efficiency, and waste reduction to minimize environmental impact and mitigate climate change. It is important to not view sustainability in production practices as a nice addition but to see it as vital for the long-term success of industry.

Worker empowerment:

Placing the well-being of workers at the centre of the production process, empowering them through skills development, training, and a supportive work environment. It is for example crucial that new technology is developed and introduced with the users in mind, helping them succeed in their tasks.

Innovation:

Driving technological innovation towards societal and environmental goals, rather than purely economic objectives. Notably, societal and environmental goals do not have to be mutually exclusive from economic objectives. In cases where they are, we are bound to see more rules and regulations turn up to counter this exclusivity.

Resilience:

Building industrial systems that are robust, adaptable, and capable of withstanding disruptions while maintaining sustainable practices. This has become ever more evident through the impact of the COVID-19 pandemic on industry.

Social responsibility:

Embracing corporate social responsibility and ethical business practices to ensure positive societal impact and stakeholder value.

How will we reach the goals and objectives?

The transition to Industry 5.0 requires a fundamental shift in the way industries operate and interact with society and the environment. Unlike Industry 4.0, which focuses primarily on optimizing efficiency and economic gains, Industry 5.0 emphasizes regenerative and restorative approaches. This shift requires the industry to rethink system design, reconfigure supply chains, focus on data transparency, and align business strategy with the goals and objectives described above. Furthermore, Industry 5.0 is rooted in an understanding that the industry doesn’t operate in a silo and thus invites actors to contribute their part by providing the necessary incentives and tools for a successful transition.

This understanding can already be felt as more conscious consumers are demanding more sustainable practices from manufacturers. Furthermore, actors such as the European Union have set up goals to reduce net greenhouse emissions in the continent by at least 55% by 2030, as described in the European Green Deal. To reach the goal, the European Union has begun to churn incentives and legislation that both support and encourage industry to make the necessary shift for the future of our planet and people.

Digital Technologies as enablers of Industry 5.0

Digital technologies serve as enablers of sustainable economic models within Industry 5.0. From artificial intelligence to distributed ledger technologies, these innovations should be harnessed to promote transparency, shared ownership, and automation guided by principles of resilience and sustainability.

When speaking about digital technologies it is central to not forget another central goal of Industry 5.0: the empowerment and well-being of workers. By emphasizing skills development, training, and a supportive work environment, Industry 5.0 seeks to attract and retain talent while fostering a culture of sustainability and social responsibility. Technology should thus be used and adapted to the needs of workers, ensuring that it enhances their capabilities and augments their contributions to industrial processes.

Insights gained by advanced tools such as Factory Harmonizer can provide a source for manufacturers to seek and facilitate process enhancements that contribute to sustainable production. Using new technology such as AI-powered soft sensors can further lead to significant reductions in the overconsumption of raw materials or energy in production, as information regarding end-product quality is more readily available to industry professionals.

Conclusion:

The transition from Industry 4.0 to Industry 5.0 signifies a paradigm shift towards a more sustainable, human-centric, and resilient industrial future. By aligning technological innovation with societal and environmental needs, Industry 5.0 paves the way for sustainable prosperity for all. Industry stakeholders who aim to prosper in the long term and who haven't done so already will begin to embrace this vision and work towards its realization and together act as a force for positive change, driving prosperity while safeguarding the planet and its inhabitants. Yet, whether one likes it or not, embracing Industry 5.0 is inevitable. As days go by, the pressure for industry to jump on board will increase and economic prosperity will follow.

This article is written using material obtained from the European Commission’s website on the topic of Industry 5.0.